We are an aluminium high-pressure foundry specialized in the casting and mechanical processing of products for various applications. Lumi Team produces casting parts for organizations across different sectors such as lighting, automotive, heating, electronics,

medical technology, etc.

ADVANCED FULLY AUTOMATED ALUMINIUM FOUNDRY

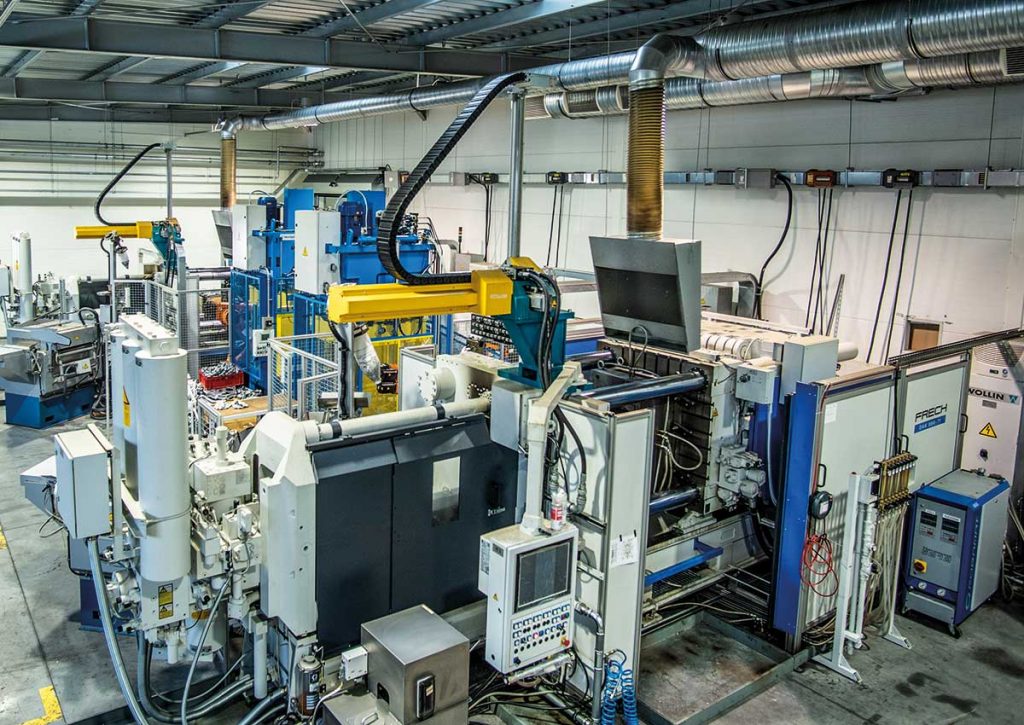

Advanced casting machines with real time casting system guarantee products surpassing expectations of most demanding clients. Our DAK series FRECH cold-chamber die casting machines with 800 and 950 tonnes locking force, work along KUKA pick and place robots with product completeness check system in two automated casting cells. We use top aluminium alloys for die casting and can die cast any workpiece up to 10 kg heavy. We work with trusted and reliable suppliers that can deliver a quality certificate and document the chemical composition of alloys sold. In our automatic refining process the alloy is further prepared for casting to ensure maximum quality. The casting cells and smelting furnaces are completed by automatic 30 tonnes TECNOPRES KZP 30 trimming presses in an effort to fully automate the whole casting process making it more efficient, cost-effective and fast.

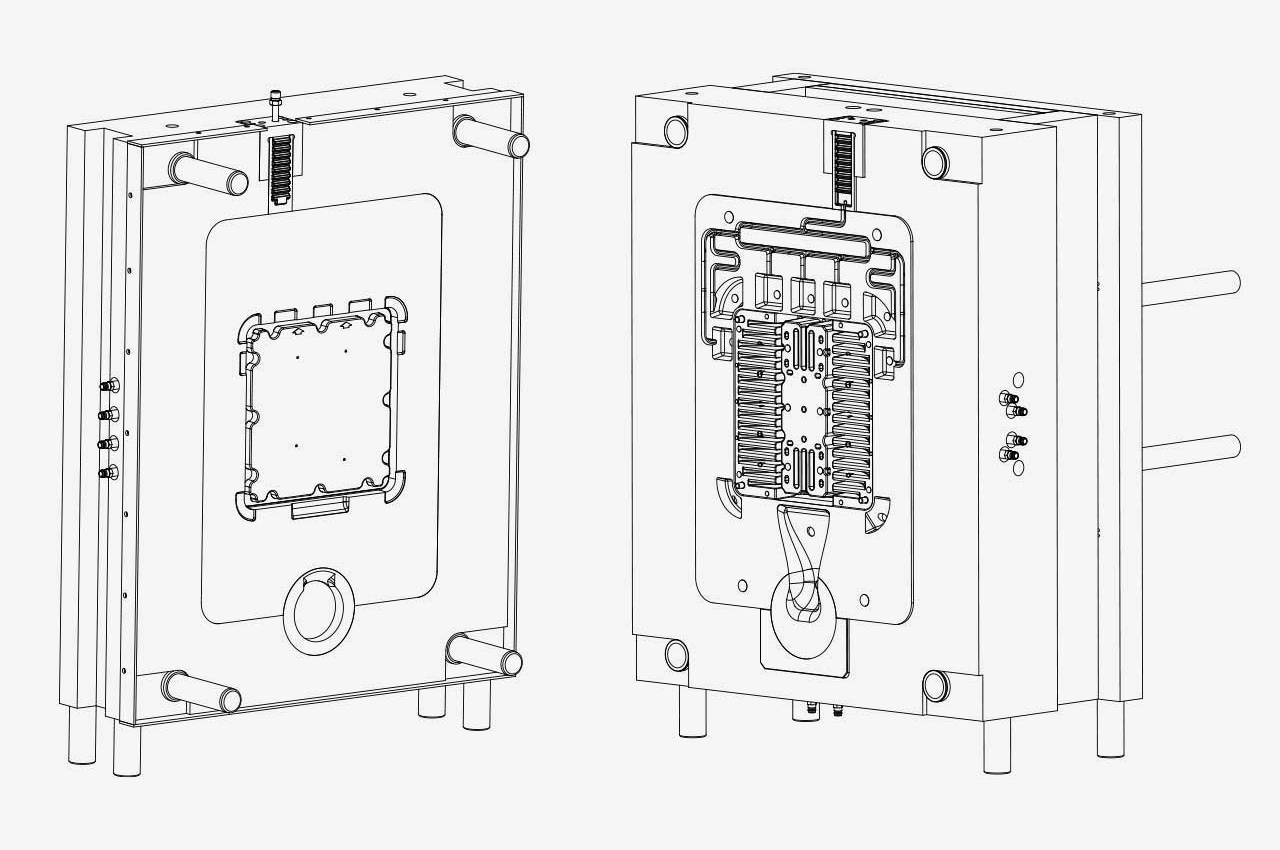

A well designed and manufactured die casting mould is key for a successful die casting process. Our expert process engineers design die casting moulds using the latest CAD software. After obligatory die casting simulations, moulds are later manufactured at our machine park, taking that responsibility off the shoulders of our clients.

OUR DIE CASTING MACHINES

In our foundry we use the latest generation of FRECH DAK SERIES cold chamber die casting machines with 800 t and 950 t locking force and real time casting system. At the casting stage we focus on achieving an optimum distribution of temperature in the mould and temperature control throughout the process. Real time system allows high-precision control of piston movement for uninterrupted aluminium casting in the mould. Therefore, we achieve the highest durability and structure uniformity greatly surpassing traditional methods.

FRECH DAK SERIES 800 t

FRECH DAK SERIES 950 t

THE ADVANTAGES OF OUR FOUNDRY

EFFICIENCY

Our machines work in the latest generation of automated cells with robots

QUALITY

To ensure the highest quality of the casting, we focus on refining the metal in the ladle

FLEXIBILITY

We are open to small series

MOQ ≥ 5000 die casts annually

Our team of engineers is at your disposal. Using CAD and CAM programs, we will design and make forms and dies according to your expectations. We can prepare any design for mass production.